MATERIALS FOR FRAMES

The most common materials for frames and spectacles

Our glasses are made of different kinds of materials. The most common materials used in making frames are Acetate, Monel, Nickelsilver, Stainless steel and Titanium. Below you can read about the materials, how we work with these and also about the EU Reach standards for usage of chemicals and colors when making glasses. The spectacle business is very regulated since frames/glasses is something you wear on your skin, in your face.

STAINLESS STEEL

Stainless steel consists mainly of chrome. This gives strength, flexibility and durability. The material is extremely resistant against corrosion. Can be manufactured very thin and is therefore suitable for temples. May contain a small amount of nickel.

Soldering: Silver solder is used according to traditional methods.

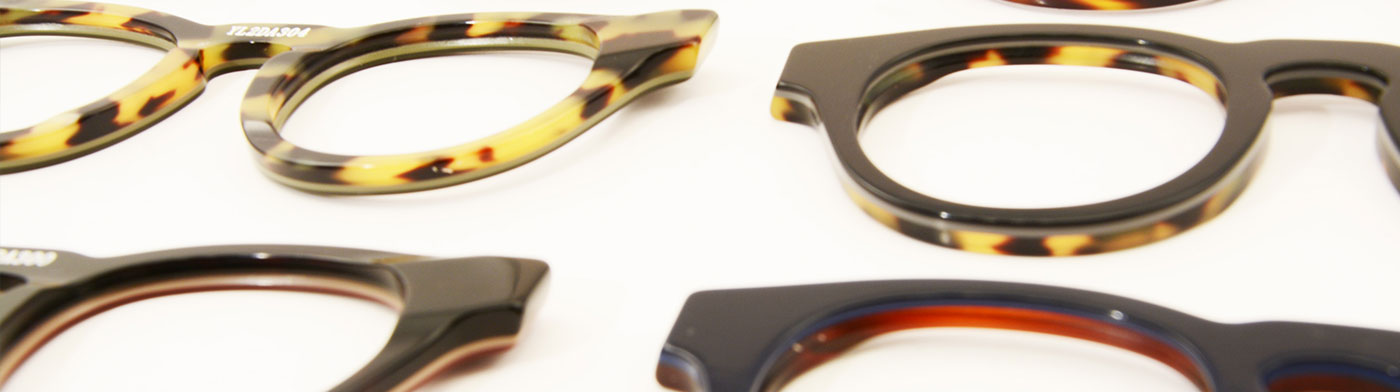

ACETATE

When people talk about “plastic frames”, they usually mean frames made of acetate. Acetate is not a plastic at all. It is a cellulose-acetate or acetate rayon produced by the acetylation of cellulose (cotton) with a solution of acetic anhydride and sulphuric acid. All additives are regulated through EU standards called Reach, not to be harmful for the user, or the environment.

Acetate frames are nickel-free, but the hinges being used on acetate frames can contain small amounts of nickel.

Acetate is delivered by a lot of different producers and can have almost any color or transparency. So, it´s a very creative material to work with.

ECO-ACETATE

Eco acetate is environmentally friendly acetate. It is produced from cotton and wood-pulp fibres using substances from renewable sources. Eco acetate is 100% recyclable and 100 % biodegradable, a conscious material for the conscious consumer. It is also Phthalate-free. ECO acetate is limited when it comes to colors and also reacts differently to aeging, sun, cold etcetera. But we look forward to a development where Eco acetate has become standard with the same usability as normal acetate.

TITANIUM

Titanium is a nickel free material that offers many advantages: low weight, high durability and a high tensile yield limit. As a result, it can be used to make frames that are very thin and yet stand up to the requirements of the users. Titanium is as strong as steel, but 45% lighter.

We uses two types of titanium to manufacture frames, Titanium-P and Titanium-B. Titanium-P is 99,0-99,7% pure, while Titanium-B, which is found in our hinge and screws, is about 90% pure. Titanium-B is harder than Titanium-P, and is thus employed where there is more wear and tear. Titanium frames are therefore the best alternative if you are sensitive for example nickel.

Sometimes titanium is used together with acetate, (ex. Titanium front and acetate temple) in this case a small amount of nickel can exist in the hinges.

The alloy material is magnesium. Since both producing titanium and manufacturing the tools needed to work the material is difficult and expensive, titanium frames are more expensive than similar frames made from other materials. The material has a silver-grey color.

Titanium-P consists of: Titanium 99,0-99,7%, Iron, Carbon, Magnesium less than 1%.

Titanium-B consists of: Titanium 90 %, Iron 1%, Aluminium 3,5-4,5%, Carbon 0,1%.

Soldering: Titanium can be soldered but requires use of titanium solder and very high heat.

WHAT MATERIALS ARE OUR FRAMES MADE OF?

Our glasses are made of a large number of materials. The most common materials used in making frames are acetate, monel, nickelsilver, stainless steel and titanium. If you are oversensitive to a particular metal, it is a good idea to find out which metals that frames are made of before deciding on your new glasses. We are currently looking at different ECO acetates to see how they can fit into our collections.

Surface coating of metal frames

All our metal frames have three-layer protection consisting of two electrolyte coatings and a layer of varnish. This makes our frames certified according to EU standards for nickel discharge.

Monel

The most common metal used to manufacture eyeglass frames is monel, a nickel-copper alloy with very high tensile strength. This alloy is highly resistant to corrosion, salt water, various acids and alkaline solutions. The material has a glossy silver color. Monel consists of: nickel 65%, copper 32,4%, iron 1,5%, manganese 1,0%, carbon 0,05%, Sulphur 0,001%, silicon 0,02%, aluminum 0,01%, titanium 0,01%

Soldering: Silver solder is used according to traditional methods.

Nickel silver

Nickel silver contains of 61% copper, 18% nickel and 21% zinc. Often being used on bridges.

Soldering: Silver solder is used according to traditional methods.

COMPONENTS

Frames

We uses primarily acetate and monel, which are easy materials to work with. If the material is not specified for a frame, it is made of acetate, monel, nickel silver, stainless steel or titanium.

Earpieces / Temple tips

We uses two types of earpieces / temple tips – acetate and thermoplastic.

Hinges

In most cases, we use traditional hinges from leading European suppliers. On more exclusive collection we have gold, or silverplated hinges.

Pads

OPO uses two types of pads – PVC and silicon.

Padarms

On titanium frames the padarms are in titanium, on metal frames the material is monel or nickel silver.

Screws

On most of our frames there is one or more screws, to the hinge, decor or the glass. These screws are made in stainless steel with one exception, and that is on our titanium frames that have a acetate covering on the inside of the titanium temples. This acetate-covering is fastened with titanium screws.